by Amanda Evans-Lara

There is vast amount of information out there on the do’s and don’ts of formulating your HACCP plan. Some aspects have been passed down from generation to generation, some are written in law and some are just plain old personal misunderstandings. Whatever the origin, this post will bust five (5) myths that you should not believe about HACCP.

Hazard Identification

The most common HACCP myth that I see when auditing and marking course assessments is that “You only need to identify one biological, one chemical and one physical hazard when you complete your hazard analysis.” This is simply not true. When you read the Codex HACCP requirements it is very clear that you are required to identify all potential hazards. This obligation is also stipulated in common GFSI recognized programs like BRCGS, SQF, FSSC22000.

Grouping Hazards

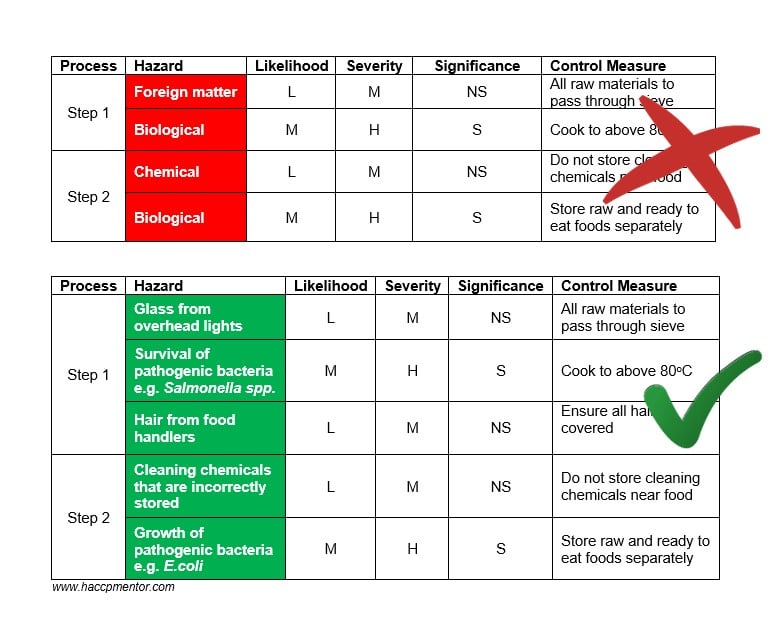

The next HACCP myth which is also related to identifying potential hazards is that “It is okay to group and assess hazards as one.” This is a common error made by lots of food businesses and is seen when a business groups and then assesses, the hazard category as one.

In fact, Codex HACCP has specifically called this out by mandating that “Hazards should be specific, e.g. metal fragments, and the source or reason for presence should be described, e.g., metal from broken blades after chopping.”

If you choose to go down the path of grouping hazards, please understand that control measures can significantly differ for hazards within a group or category. For example, both glass and metal are categorised as a ‘physical hazard’. However, the way you would control potential glass contamination from over-head lights will be very different to the way you control metal from worn or damaged utensils.

Validation and Verification

The third HACCP myth is that “Validation and Verification are the same thing.“ Well guess what? No, they’re not. Validation is what you do BEFORE, and verification is what you do AFTER. I know it can be confusing and it doesn’t help that they start with the same letter.

Let me expand on this further.

Validation – is what we want to do, going to work. Is it going to achieve the outcome that we desire and require? An example of this would be, we say that we are going to cook a food to a particular temperature because we want to make sure that no harmful bacteria remain. To validate the temperature chosen, we could refer to legislation, scientific journals or other data that supports the cooking temperature we have selected will kill the harmful bacteria.

On the other hand, verification is best defined as being the things we do to see if we have actually done what we say we were going to do. So, in the above example, with the temperature to kill the harmful bacteria, we would check or verify that the food actually reached the set temperature. This would be done through testing the temperature of the food.

Flow Process Charts

The fourth HACCP myth I am going to bust today is a classic. I get asked questions about this all the time. “You must use traditional flow chart symbols when documenting your process flows.“ Keep in mind we are not still in the 90’s with this one. You can document your flow process chart however you like just as long as it is a truthful pictorial representation of your actual flow chart.

My post on developing your HACCP food safety flow process charts is a great starting point to see examples and handy flow chart development tools.

Auditor CCPs

HACCP myth #5 is that “The external auditor can define your CCPs.’“ This is so far from the truth it is not funny! I don’t know how many times I have been told by members of the HACCP Mentor community that the reason they have a certain CCP identified is because the auditor said that is what it needs to be. The only way that CCPs should be defined in your business is by following the principles of HACCP.

Continuous improvement opportunity

Take a moment to review your HACCP or food safety plan to see if any of the five myths mentioned apply to you. You can also share your thoughts by leaving a comment below.